The Benefits of Using Automated Valves

RH Business Marketing Solutions

Automation assists with activities and processes without requiring employees to physically participate in their implementation, reducing manual labour. Valve automation is very useful for managing flow in piping systems that require precise control or fail-safe emergency shutoff. A closer look at the advantages of using automated valves reveals their overall industrial influence, improved output control, and higher manufacturing and production efficiency. Let’s have a closer look at those.

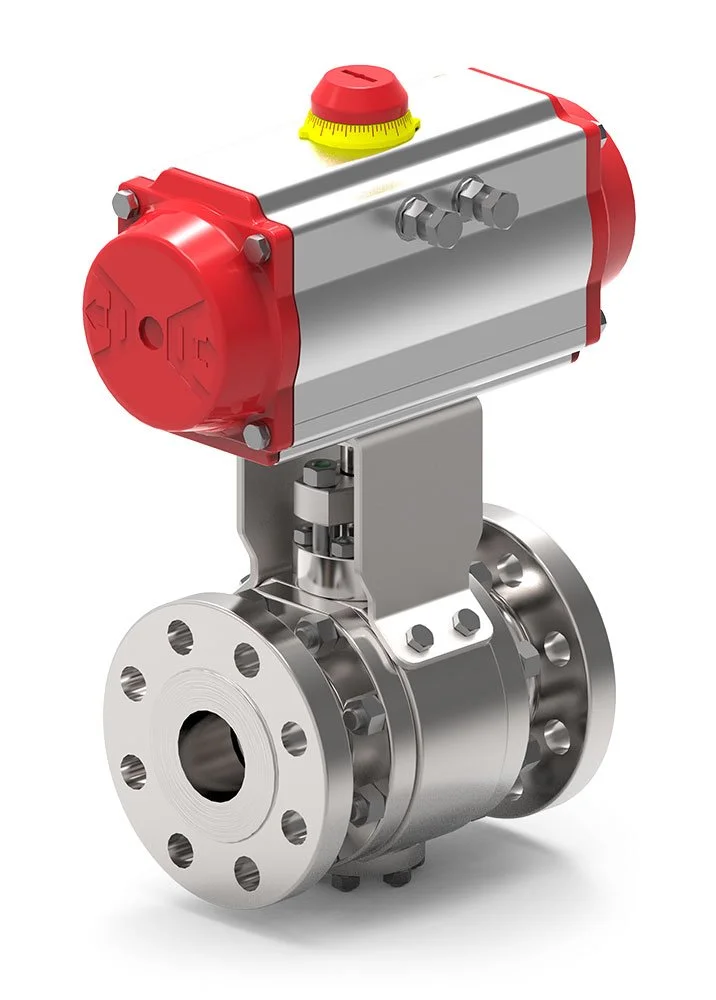

Automated Valve Actuators and Their Impact

Automated valve actuators have an impact on a variety of manufacturing and processing operations, including hazardous materials, oil and gas, chemicals, food and beverage, and others. Manual operating valves entails a number of dangers:

● The operation of manual valves takes a long time and requires a lot of effort.

● Manual operation raises the possibility of human error and may result in higher operational costs due to waste from destroyed products.

Using Automated Valves to Increase Output

Using automated valves to improve output control helps reduce expenses associated with product waste. Automated valves do not require the presence of an operator, allowing them to continuously monitor and modify flow across a system. This principle operates similarly to a hot runner manifold, a device used in injection molding systems to regulate the flow of molten plastic. Automated valves and devices like the hot runner manifold uphold operational efficiency even during outages when paired with battery backup systems that provide an emergency power supply or, at the very least, securely stop the present process until the utility is restored.

The use of automated valves to improve output control helps to reduce expenses associated with product waste. Automated valves do not require the presence of an operator, allowing them to continuously monitor and modify flow across a system.

They can continue to operate even during outages when paired with battery backup systems that provide an emergency power supply, or at the very least securely stop the present process until the utility is restored.

Using Automated Valve Actuators to Improve Safety

In locations where severe temperatures, pressure levels, unpleasant odors, flammable components, or other variables have the potential to cause serious accidents, actuator valves aid to control constant operating levels and maintain safety. Automated valve actuators return to fail-safe settings in an emergency, avoiding accidents, environmental risks, machinery or structural damage, and other disastrous effects.

This type of valve also enables remote access to valves that would otherwise be comparably difficult or impossible to reach safely and physically return to a safe position.

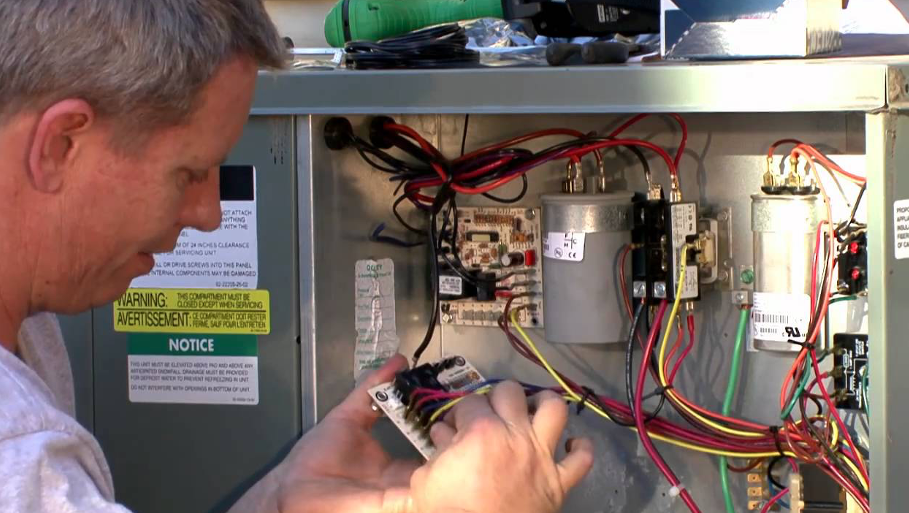

Valve and Control Automation Provides a Safer Work Environment

Valve automation improves employee safety while also ensuring compliance with industrial laws. Automated valve and control systems are used in systems that deal with temperature extremes, high pressure, and other components that could result in serious accidents.

Furthermore, in the event of an emergency, automatic valves and equipment revert to their fail-safe settings. This reduces the risk of environmental dangers, accidents, and additional property damage.

Accessibility to other valves that are difficult to reach is made possible by automated valves. They then physically place them in a more secure location.

Operational Costs are Reduced by Automated Valves

Valves and equipment that are automated can help to reduce waste. This is due to the fact that there are no measuring inaccuracies caused by human error.

Using a variety of automated valves in your system will reduce the amount of personnel required to operate it. This results in a huge reduction in labor costs. It also cuts down on the time it takes to create a specific level of output. You can use the extra time to start a new product line or make enhancements to existing ones.

More Efficient System

Manually operated valves require regular human intervention in order to function properly. As a result, the system is almost always turned off and on. Running this takes a lot of energy and fuel.

Automated valves, on the other hand, maximize flow efficiency.

Concluding Thoughts

Automated valves are used in a variety of production operations. They have a high level of precision when it comes to managing flow in systems. As previously stated, they prevent a number of potentially dangerous scenarios that could result in workplace injuries.

Furthermore, they require less labor because only one or two engineers are required to control the entire system. Hence, make sure to consider this solution, along with automatic solenoid valves for your upcoming operations to increase productivity and reduce cost.

Guest Contributor: Kate Anderson